WHERE QUALITY TAKES SHAPE

WHERE QUALITY TAKES SHAPE

Advanced technology, expertise, and dedication. Tailored solutions that exceed our customers’ expectations.

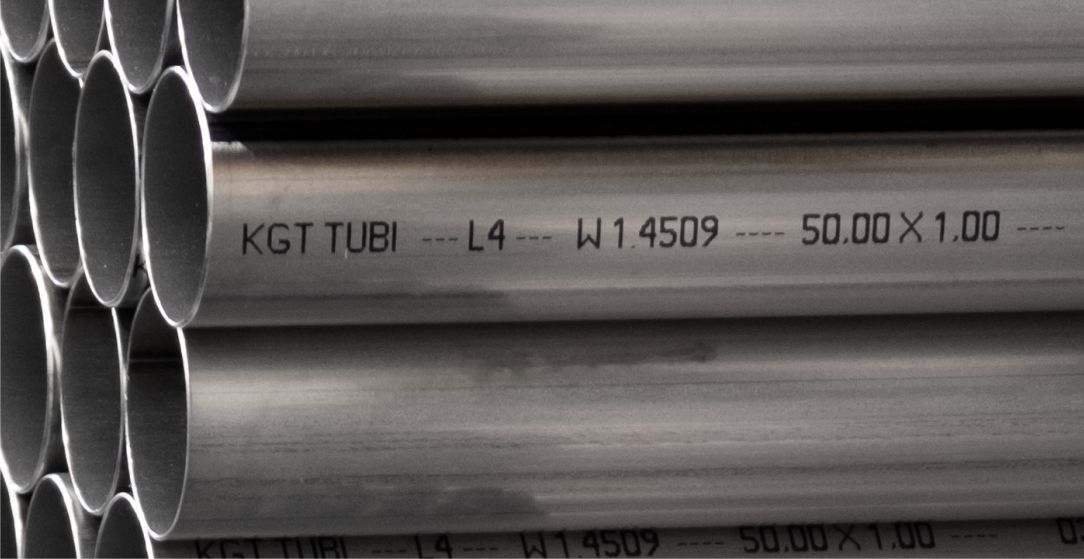

The tubes we produce are longitudinally welded using laser technology, a process that minimizes the heat-affected zone and produces a very narrow bead, characteristics particularly suitable for welding both ferritic and austenitic steels.

Moreover, laser welding is also particularly suitable for special materials such as Duplex, High Nickel Alloys, and Refractory Steels, for use in corrosive environments at high temperatures.

The custom cutting department allows us to provide tubes in customized lengths through a mechanical cutting process. This process preserves the inner surface of the tube from contamination by fused particles typical of other processes (such as laser cutting), improving the performance of the tools used in the customer’s process.